CellBlock's FCP Technology Blasts Through Testing

Companies rely on the CellBlock line of fire containment cases and cabinets to extinguishlithium-ion battery fires and keep valuable cells and team members safe. Dylan Vandemark, VP of Product Development at CellBlock FCS, tests above industry standards to ensure the products will perform in an emergency situation, and these fire containment panels perform.

Companies know about our fire rated fabrics, but the star of our ultimate protection cases and cabinets are more than just safe storage for high watt Lithium Ion battery cells, but charging, and simply genius fire suppression technology.

Aeroblaze Laboratory once again assisted us in our development of this FCP technology, with a concrete panel capable of the highest heats. The testwas a variation of FAA 14 CFR 25.1193(d), Advisory Circular No. 20-135, DOT/FAA/AR-00/12, Chapter 12 – a powerplant test that runs in excess of 1093 degrees celsius (2000 degrees Fahrenheit).

This test is extreme. At CellBlock’s request, the lab completed 30 minutes of testing our proprietary fire containment panels.

The FCP Panels were originally designed as a fire suppression and safety solution for the storage or transportation of lithium-ion batteries or other dangerous goods. Over the years, however, CellBlock has adapted and transformed this product to serve a variety of purposes in numerous industries.

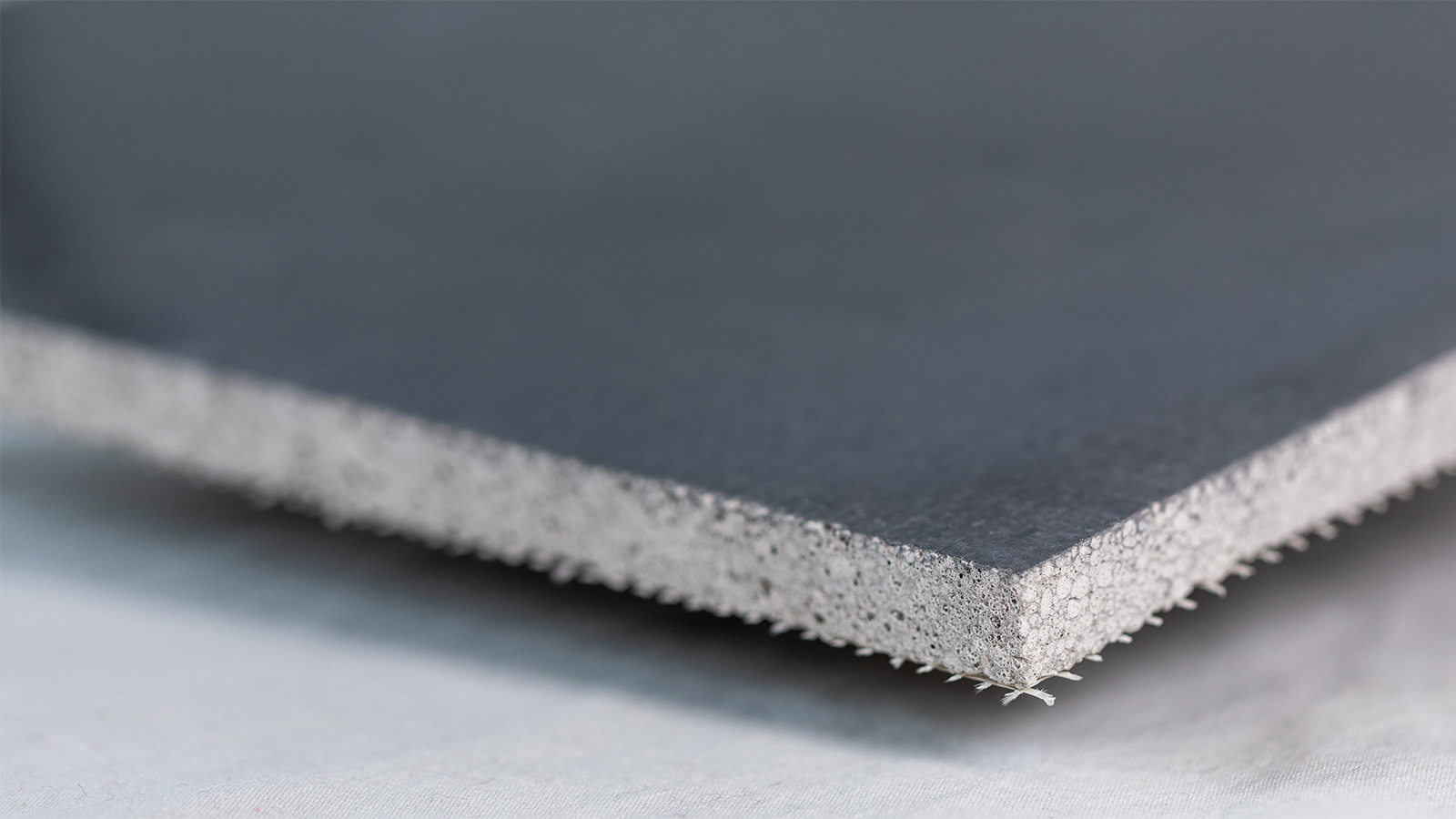

Our panels are made, through a proprietary process, from environmentally friendly recycled glass aggregates (CellBlockEX), bound with multiple pozzolans and other additives. Panels consist of a core using three different grain sizes of post-consumer foamed glass ranging from 500 microns to 4 millimeters and are finished with a cementitious powder coating containing glass and basalt fibers. CellBlock FCS is an ideal substrate for the construction of high-temperature fire containment shipping and storage containers, ballistic test chambers, fire corridors and floor underlayment.

Safer Battery Containment

Safer Battery Containment

CellBlock’s versatility allows it to meet the fire protection needs of multiple industries including manufacturing and production facilities, building construction, transportation of dangerous goods (land, sea and air), renewable energy storage, military applications (from storing drones to transporting trigger mechanisms) and for archival/museum safekeeping. Lightweight, environmentally friendly, durable and flexible, the panels can be used to line existing structures from walls to shelves and floors or manufactured as self-contained boxes, making them an ideal solution for every industry.

The powerplant test was used on our proprietary textiles, proving its might. At 5 minutes with no burn-through materials are considered fire resistant; at 15 minutes they earn a fireproof rating. Our textiles lasted 30.

Cellblock FCS is revolutionizing the safe handling, transportation, and storage of lithium-ion batteries and other dangerous goods. Most recently, they added an Exhaust monitoring system upgrade available to all cases and cabinets.

The FCP technology has been deployed and applauded to some of the safest spaces on Earth, in the skies, on Yachts, mine shafts and even homes. Cases and cabinets are customizable, and can be easily configured for your exact needs.